Prodotti Speciali… The rare look inside the Campagnolo Factory… The Holy Grail of the Cycling Industry!

When I first fell in love with road cycling, I started to hear about the mythic componentry coming from Italy that truly made a good bike great. As I started to see images in the magazines of Euro Pro races, I not only noticed the weird looking shifters (compared to what came spec’d on my bike) but started to stare in lust. The shape was sexy and I couldn’t help wishing my bike got me as turned on. I wanted to feel up those shifters and run my hands along those smooth curvy brake calipers and derailleurs from those better bikes….often bikes that weren’t as familiar to me yet, but I had seen and heard a little about, again though those magazines. I ventured to more shops and more shops widening my circles and started to get a chance to see more of these dreamy bikes in person…Colnago, DeRosa, Pinarello, Time, Guerciotti…..

Shortly thereafter, I bought my first bike equipped with Campagnolo

My starter bike was to have lasted longer, but that plan wasn’t going to work any more for many reasons. I wanted something better and wanted into the Club of the nicer bikes. Relative to my income at the time, I went big. I was riding every possible spare moment that a person living and working in NYC could. I started to long for cycling as the best moments of the week. I needed a better bike and I needed it to be more Pantani than my Waterloo machine was.

As the years passed and I became more and more in love with Campag, I started to learn everything I could about the company’s history and the lineage of components. When the internet really grew to be the information repository that it now is, more info became available to me, more pictures of the racers, the components, but only a few of the company’s employees and factory itself. I started to realize how rare it was, to get inside information from the major media sources, while it was just the opposite for their competitors. So many manufacturers in the industry seemed to welcome in people as part of the marketing efforts, while Campag seemed to be building some of theirs based on this secrecy, that perhaps teased people enough to keep them wanting more. I was lured in and always wanted more. Years later, I went from just user to dealer and user. My addiction in full swing with no remorse.

As East West Bikes evolved from Banning's, our identity has always been closely associated with Campagnolo

In a modern world filled with concept stores and marketing engines that draw people to more mass produced products and brands, East West has been an oasis for those still looking for a guide through the modern world of Campag 11, as well as a trusty mechanic to overhaul the 9 speed shifter and make that group set of fifteen years ago still shift along. Although the past is amazing, their current and future have us mesmerized. Some of their recent innovations (Ultra Torque cranks, skeleton brakes, 11 speed mechanical, the re-introduction of Super Record, and of course…EPS) are as hot to me as looking at a sheriff star hub or Super Record crank from back in the day. We are certainly not the biggest volume Campag shop, but we are disproportionately skewed toward it in terms of sales. We want to be that place that people think of first, when it comes to anything involving Campagnolo. I know there are shops that sell more, even here in So Cal, but I don’t know anyone who bleeds it more.

“The years of curiosity and secrecy and mystique culminated into one phone call.”

About a month ago the blood letting paid off. The years of curiosity and secrecy and mystique culminated into one phone call. From Mike McGary, the Campagnolo brand ambassador for Quality Bicycle Products. QBP is the largest distributor of Campag components and wheels for the US and is our main supplier of the dopest dope. We had developed an amazing relationship with Mike as we all bonded right from the start a few years ago. He saw us as one of his key shops in So Cal and we saw him as a critical relationship and resource in our quest to be the area’s best known Campagnolo expert. I answered the phone and responded in short strange answers, probably from the shock. An invitation from Campagnolo SRL and QBP to travel to Rome to participate in a Grand Fondo sponsored by Campy, followed by travel to Vicenza….to visit the factory. Thankfully, a long running agreement between Banning and myself, put me in the game (I will owe Banning forever for the record) and of course we said YES!

As I’ve written many times before, this blog will not simply re-type what can be found in many other places on the web. As such, I will not give a detailed history on the brand’s namesake or what the company has produced. In summary: the quick release, the derailleur, the ErgoPower integrated brake lever / shifter, 10 speed, 11 speed, and of course the winged cork screw. Tulio Campagnolo retired from racing to start the brand to develop the products that he knew were needed to take bike racing to the next level. Formed in Vicenza, Italy (Veneto Region), the company is still based in that beautiful historic town. While he passed away in 1983, his son (Valentino) has been at the helm ever since. Unlike his father, Valentino is not a cyclist, but he is an amazing leader and has maintained the brand in a way I know his dad would be proud. They employ several hundred people, split between several facilities in Vicenza, Romania and Asia. Almost all manufacturing for Chorus, Record, Super Record, and EPS group sets is in Vicenza. Almost all manufacturing for Zonda, Eurus, Shamal, Bullet, Hyperon, and the Bora wheels is in Vicenza. Their Fulcrum counterparts as well.

Getting access to the Vicenza factory is as common as getting in the Wonka factory

Over the years, non press people have been limited to literally a handful. A couple of years ago, while in nearby Treviso, I tried. I had friends with the right connections try hard to get me in, but with no luck. No chance to sneak a peek behind the curtains. But now, QBP was permitted to invite four shops. Along with East West Bikes, they choose Contender (Salt Lake City), Velo Tech (Palo Alto), and Bicycle Pro Shop (Washington DC). The four of us have several things in common, but most importantly, Campag passion. Campagnolo and QBP wanted those that bleed the holy winged logo in our veins. And I think they assembled an amazing group. I will cherish spending those five days with the others for the rest of my life. They were each wonderful people and it was so much fun hanging out together and sharing with each other and learning from each other. Thank you Ryan, Alison, Tom, Aimee, and Tony.

The trip was amazing. Seeing Rome and all its beauty and history was incredible. Campy’s marketing guru Josh was an enormous help to our group while in Rome. He is an American that has the honor of working in Vicenza and its obvious that his pride and spirit are huge. He is a younger member of the team which helps demonstrate that Campagnolo is as much about the future as about celebrating the past.

The Grand Fondo was an incredibly well run event, despite local politics eliminating the “long” course. The medium was good enough for me. Passing under the start sign that read Campag, with Valentino waving us all through was just awesome. Although eating breakfast at the table next to him several hours earlier was pretty cool too. Later that night, I had an incredible opportunity to sit with Dino Cento, the Campag OEM Manager, at a pub in one of the many ancient neighborhoods of Rome, who answered almost all of the questions I could think to ask. I tried to ask everything that I could think of….disc brakes, Bora clinchers, next generations of EPS, the relationships (perhaps even collaboration) with Shimano and SRAM (hereafter referred to as the “S” brands), mountain bike components, and so much more. I will not publish any of his answers. I wasn’t sworn to secrecy at all, but I have too much respect to just simply kiss and tell. I only get drunk once a decade, so it will be hard to pry those answers from me out of respect to the heritage and philosophy of the brand. A complete 50th Anniversary Groupset gift might open me up, however… I will reveal that solar powered wireless fourteen speed EPS is not coming soon.

“But it was the factory tour that got me on that plane, and it certainly didn’t disappoint. It surpassed all expectations.”

We arrived at the Factory at about 11:30 am. on Tuesday (10/15/13) in a van driven by a Campag employee. There was a long awkward pause at the gate. Each of us was nervous. Each of us knew the mysterious aura of that building and the challenge of gaining entry. Why is there a delay? Did we get our hopes up and fly all the way over here only to find they’ve changed their minds at the last minute? Did someone in that van have a GoPro attached to their chest transmitting data to one of the “S” brands? Pause….silence in the van….pause….nervousness….Naw…its just Italy, adhering to its own sense of time. A few minutes later we were in the lobby. Surrounded by a small collection of bikes that served as a history lesson of Electronic Power Shifting (“EPS”) evolution. Mode buttons on the ErgoPowers all the way back to the beginning are just a few of the familiar parts of EPS that were there in the beginning twenty-five years ago! A few minutes later, we were greeted by Dino. He ushered us upstairs to the the Record Sala conference room that I had seen in pictures from one of the recent limited visits of a well respected journalist. That room as well as the rest of the building was a well preserved time capsule of the early 1980s when the current building was built for the brand. We sat through a terrific presentation of Campag’s recent global performance given by Dino. We were then joined by Michele Cardi, the Global Sales Manager, who at the end of the presentation escorted us to the Factory cafeteria to join him for lunch and discussion.

A private lunch room was set up for us, which also seemed like a throwback to the early 1908s. It reminded me of my days in grade and middle school. Strangely familiar and comfortable. Incredibly unpretentious and practical. Michel sat at the head of the table and wore a huge warm smile. Obviously, incredibly intelligent and talented, he asked us wonderful questions that spurned a long and fascinating dialog. History vs. the future. How to compete against the marketing geniuses of the “S” brands without sacrificing too much of the innovation and quality that Campag stands for, finding the place for products like Veloce and Scirocco in a world where people only think of Record or Chorus, offshore manufacturing, complicated distribution models, and how they can better support their dealers. Much like all meals in Italy, there was a delicious pasta course, followed by a main course, and capped with a dessert and coffee. All the plates bore the famous winged logo and it was an honor indulging in that meal.

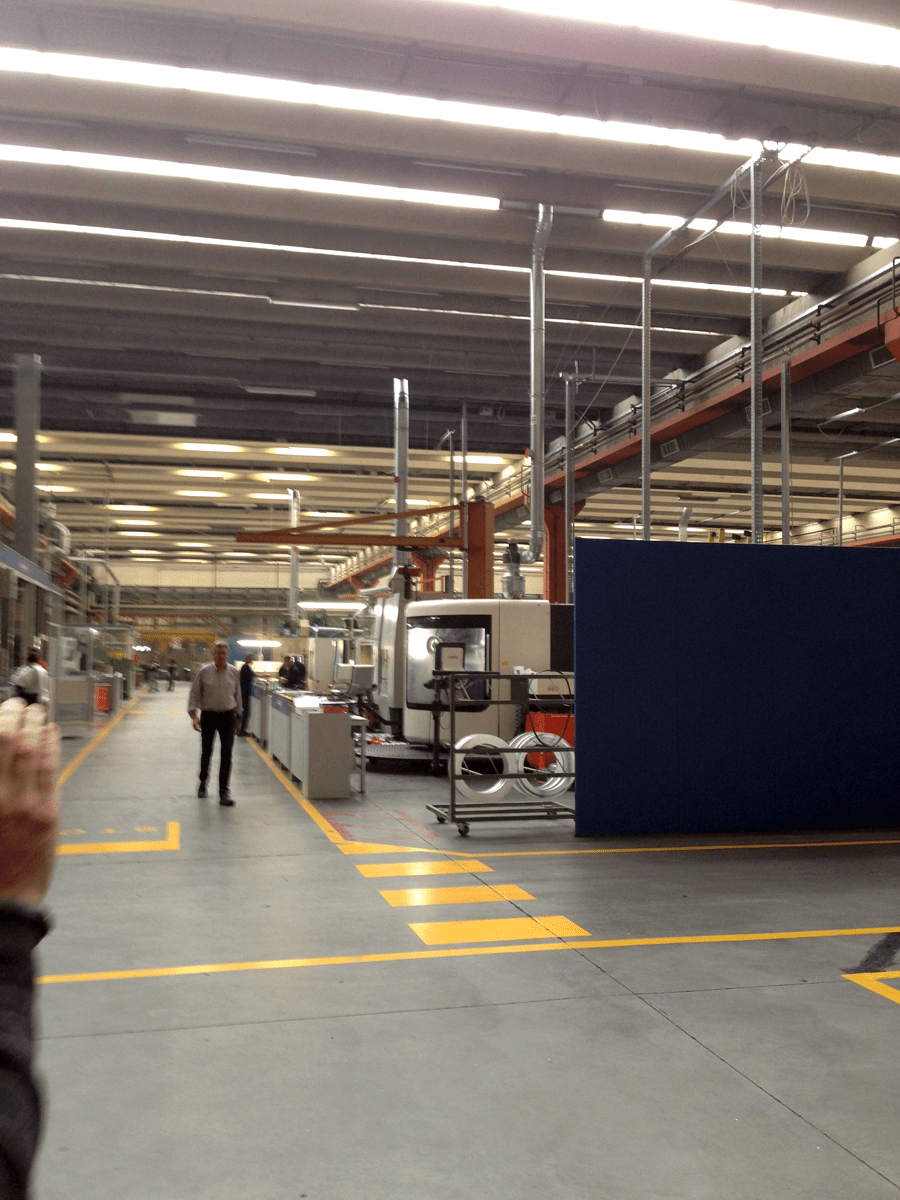

After lunch, Dino returned to conduct the tour. He as been with the brand for almost thirty years in a collection of different roles. His previous role was Production Manager, thus making him the ideal person to conduct the tour. Given that these tours are so rare, they do not have a boilerplate way of running through things, but Dino did an outstanding job. We started in the loading dock that receives rare materials: aluminum, steal, titanium, and carbon fibers. We then proceeded methodically through the floor stopping at each work station and machine to see that day’s activities. To summarize, there are many different types and sizes of machines that stamp and manufacture individual parts that later get assembled into the actual components and wheels. As such, its all about the molds. They design and develop molds in house to make everything from small fasteners, rims, ErgoPower bodies, shift wafers, cogs, chainrings, spokes, etc. Different machines interact with the different molds to transform raw materials into the actual parts. Each part then undergoes many many processes to become a finished product. Then assembled into the final components and wheels. Finally, packaged carefully into the boxes that have become as much a part of the tradition as the unmistakable scriptive Campagnolo logo that can be recognized by even the most casual cyclist. That day was all about cogs for cassettes and chainrings. A single chainring or cog undergoes a minimum of six stages of machining before it becomes ready to assemble into the finished cassette or crankset. The following day or week might be the ErgoPower internals, or the USB or CULT bearings, or the sensitive rear derailleur springs, or the front derailleur cages, etc. We also observed the area where they were actually creating the molds. That day, all focus was on completing the remaining molds for the Bora 35 rims. Obviously front differs rear, each mold consisting of four sections.

One of the areas that does not change with differing molds based on the day or week was the chain production area. The individual outer and inner plates and stamped out using similar machining as we had observed in the previous areas. The individual rollers and pins as well. Additional machines then start to assemble these differing parts into the actual chains. The chains are produced in one long strand. So many steps, its hard to recall it all, but eventually, individual chains are counted and cut from the long strand. Further steps are taken to ensure the appropriate quality control. Finally, the magical lubrication is applied….anyone who has ever unwrapped one of their chains knows just how amazing that first lubrication is when it comes out of the box. These machines may be making any of the following depending on the day: Record 11, Chorus 11, Record 10, Centaur 10, Veloce 10, Record 9. Valentino is very proud of the chain process and has vowed to never let that out of the Vicenza facility and now I understand why. Often over looked, it may be one of the most impressive components they produce. Just seeing them hollowing the pins for Record 11 is hard to adequately describe. The entire process seemed to be a perfect balance of technology / equipment combined with the human touch that each step requires. I smiled and nodded at the chain guru and realized that his hands had touched the hundreds (maybe thousands at this point) of Campag chains I’ve installed. Its always been impressive to unravel them before, but now I’ll probably smile a little more each time I open one, as my mind travels back to those precious moments watching the process and the people involved.

All of the historical molds dating back to C Record (1984ish) are well preserved and catalogued. In theory, they may be able to reproduce products of the past with this treasure trove of molds. Financial obstacles would probably make it unfeasible to do so, but the fact that the molds still exist and could be used again, give every fan the real dream of owning a brand new pair of down tube shifters again….or for the first time.

The next area we visited was the product testing area

Led by a very nice gentleman, whose name I didn’t quite catch and didn’t speak much English, which isn’t unusual in Italy But the eye contact we had made me understand his passion and pride. His department is as critical if not more than any other in that facility. There were many workstations that had differing ways of “testing” the extremes of different components and wheels. We observed a fully functioning EPS group set submerged in a tank full of mud (thick heavy nasty stuff that made a typical day in the Spring Classics look clean). And it was shifting just fine. We saw a machine that tested the effects of heavy humidity and salt on varying components (of the many things in the tank was a CULT bearing that still spun very nicely). Another machine provided a simulation of huge rock impacts on rims. Of course, the obvious ones, like how many shifts the EPS ErogPowers could withstand before failure, or number of times a derailleur could move before failure, or Power Unit charge times, etc. One machine tested the extremes of decals on the rims – the moisture and other circumstances that would cause them to peel. This entire room gave a huge perspective to the age old bike shop inside joke known as JRA (I don’t know what happened Eric, I was just riding along….Yeah yeah. As Tom from Velo Tech joked, you dropped a freaking refrigerator on the spoke, thats how it broke). Products from other manufacturers ware undergoing the same tests. Again, I will not kiss and tell and provide any details, other than to acknowledge that it seemed to be a fair cross section of the Industry. I also saw Campag products being tested that are probably a few years away from release….There are some goodies on the way kids, that much I will tell.

The day concluded with a quick viewing of the onsite warehousing for wheels. Stacks of boxes so high and deep, its hard to describe. Each with those familiar labels on the outside that I’ve unpacked hundreds of times in the shop such as “Hyperon Two Clincher HG / QBP.” I believe that the wheel lacing and tensioning occurred in a nearby facility that is also where they do Fulcrum. I’ve heard Dan Large tell stories of those truing machines, and I was a little disappointed at not seeing it, but I saw so much, it would be silly to actually complain.

Dino seemingly knew everyone on the factory floor as well as every single part of each process. He was able to grab items at varying stages of production and describe the stage of the process and why each was as critical as the next. He spoke with passion about each item, as I’ll never forget how he demonstrated the benefits of each upshift ramp on the modern XPSS 11 speed chainring. As far as I was concerned, Dino was the Campag genius I had always hoped to meet (on that side of the Atlantic, as I will always have my beloved Dan here). He is a triathlete by background, and I’m sure his approach to events is just as methodical as his knowledge of the company and its products. Like everything else Campagnolo, Dino’s passion was huge and genuine.

Ironically, they were somewhat uncomfortable with the general state of the factory in terms of cleanness, but I was rather impressed. Having observed many manufacturing facilities globally (cycling related and other), I thought the work stations were clean and organized. A few shavings on the ground is par for the course and doesn’t warrant embarrassment. But Italian pride is part of the process. That said, as impressive as the tooling was, the focus and diligence of each of the artisans working that day was by far the most impressive part of the factory. These were people that were so proud and focused on their work. And it showed. I know a lot of American work places that could benefit by following the work ethic example I witnessed.

Five hours went by in a flash. I could have stayed there for 20 hours, but nothing lasts forever. We finished with lots of group pictures outside the building and in the lobbies. We were not permitted to take any pictures while with Dino, although Michele permitted a few, which I have tried to include as many here as I could. It would have been great to document the day with more pictures, but they let us in which is a huge step. Its hard to say if this was the beginning of a new era where more people will get that opportunity or if I am now part of the select few who have had the chance.

As our final Italian light started to disappear from the sky, Dino took us into ancient Vicenza for a tour of his adopted and beloved city. It was beautiful and magnificent. And his passion for that ancient city mirrored his passion for the Company. He showed us intricate details of the old church and the piazzas. Through his eyes, I imagined the ancient peoples of Vicenza shuffling through those quaint streets, paving the way for the eventual Tulio and his brand of innovations to settle in and begin the journey. It was so easy to fall in love with that gorgeous city. That walking tour was magical.

That evening we dined with Michele. Much like our lunch, it was candid and captivating. Michele is newer to the Company, but its obvious that he has found his home there. He is another glaring example of this Company's talent. We spent some time on specific current products and we also focused on the big picture future of the brand. Yet another incredible opportunity to get an audience with one of the true few with a vote at the Brand. We went long as no one wanted this magnificent day to end. Everyone at the table exhausted their curiosities, asked the questions they'd travel to Italy to ask, held onto the feeling of being inside. We could have stayed forever, but planes were leaving early in the morning and it was time to end this grand celebration

In some respects, it was moments like this made me want to join the industry. Cycling is about passion. Cycling is about heritage and tradition. Cycling is about finding the perfect balance between technology, innovation, style, function, and beauty. There are about three or four brands that actually can claim these adjectives as their mantras, but none more so than Campagnolo. And no brand is more important to me. Its that shared passion that makes me good at what I do and un-deserving of these fucking god damn Yelp reviews. I've often said in jest (but its true) that I would tattoo Record across my chest if my Jewish mother didn't share the planet with me.

Again thank you to Mike and the entire QBP family for selecting us. Thank you to Banning for giving me the opportunity to make the journey. And a very special thank you to Josh, Michele, and Dino. To me, all of the Campag people that I had the honor of intreating with are now friends for life. You are why I do this with my life. I look forward to many happy times, together as a team.